Physical properties of resins conventional ion exchange resins consists of a cross linked polymer matrix with a relatively uniform distribution of ion active sites throughout the structure.

Ion exchange resin column design.

How to design an ion exchange resin system.

Ion exchange processes can be conducted in continuous or batch mode with most water treatment ix processes run in a continuous mode.

Whether you re weighing potential treatment strategies looking for ways to get the most out of your existing ix resins or simply curious about ix chemistry you may be asking what is ion exchange resin and how does it work.

Rohm and haas ion exchange ion exchange introduction 4 fd sep 2008 to soften water you take a cation exchange resin on which the mobile ion inside the beads is sodium na and you pass the hard water through a column filled with the sodium form resin.

Usage examples continuous ion exchangers are used when it is imperative that product be continually generated.

Strong acid cation resin ion exchange resin that will readily give up a proton over a wide ph range.

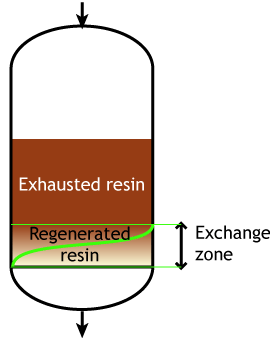

Therefore the same procedures used for the design of adsorption columns may be used for ion exchange columns.

O the scale up approach o the kinetic approach.

1 2 minutes column height.

The contacting techniques are almost identical.

For example metal contaminants are.

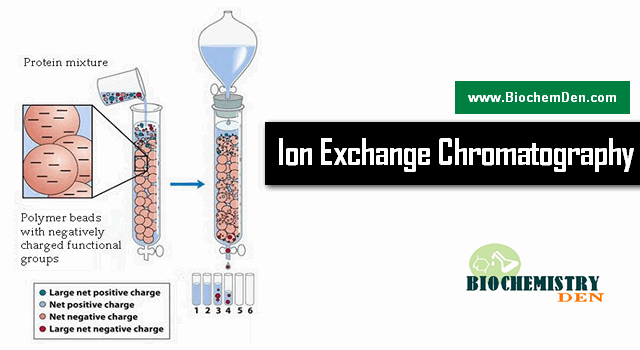

Various exchange active groups at which ions accumulate are built into the exchangers.

4 each with a capacity of 120m3 h surface loading.

Design procedures the breakthrough curves for an ion exchange column and an adsorption column are similar.

A cation exchange resin with a negatively charged matrix and exchangeable positive ions cations is shown in figure 1.

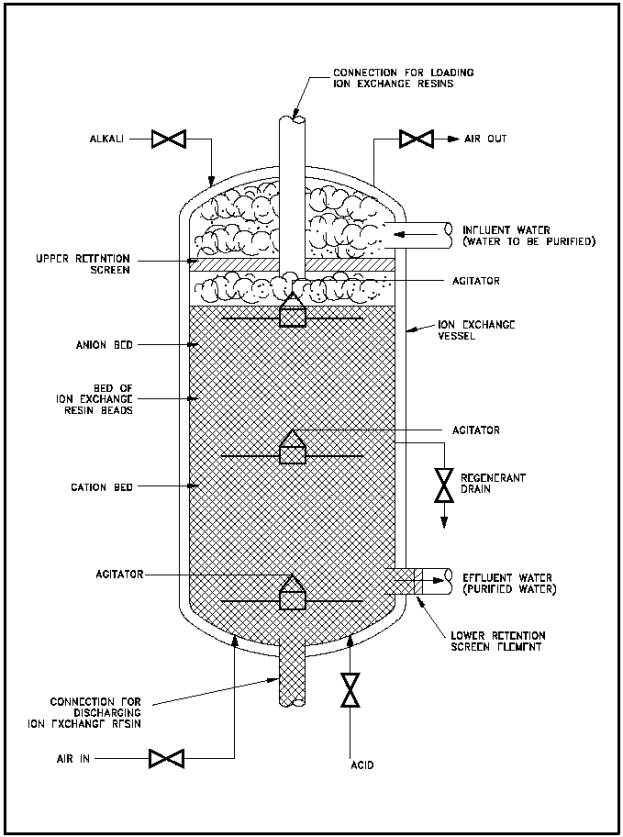

Continuous ion exchange processes take place in a column or vessel containing a deep bed of ion exchange resin beads.

While many of us have heard of ion exchange ix resins few of us have a grasp on how the technology actually works.

Ion exchange materials are.

In the exchange process the ions of the solution to be treated are exchanged with accumulated.

Strong base anion resin.

Ion exchange takes place in one column while the resin in the second column is being regenerated resulting in continuous operation.

Water typically flows down through the resin bed.

Development of column design criteria 16 8 ion exchange process design case study.

Continuous ion exchangers consist of two columns in parallel.

The hardness ions ca and mg move into the resin beads and each of these divalent.

10 days material cost of resin per m3 water produced.

Ion exchange technology ca2 2na operation 2na ca2 regeneration resin description of process ion exchangers are synthetic resins organic polymers.